STRAIGHTNESS & FLATNESS MEASUREMENT

FORM TOLERANCES

· It is related to form or shape of the component whose size or dimensions are controlled by the tolerances known as Form tolerances.

STRAIGHTNESS

· It is the phenomenon of uniformity of cross section of material throughout its length.

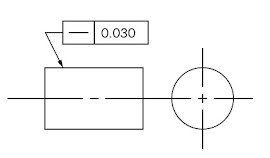

SYMBOL

· It has two different concept one of surface straightness and axis straightness.

· For surface straightness it is the permitted value given which is the distance between the upper end and lower end of irregularity on surface.

· It is measured by using a plunger type dial gauge.

Dial gauge method for checking of straightness

· Set the dial gauge at zero level.

· Place component on surface plate & Mark a straight line on a component.

· Move the dial gauge in such a way that the end point of plunger is touches to the surface of component.

· Record the maximum and minimum reading of plunger dial.

· Difference of maximum and minimum reading is the straightness of that component.

CMM method for checking of straightness

· Straightness is measured by using CMM with almost zero error although above method is manual so there is chances of occurring error while checking.

· It is also very easy method of checking straightness.

· The straightness is measured with stylus by lightly placing on the surface of component because it is very sensitive.

FLATNESS

· Flatness and straightness is the same concept except straightness measures only line element and flatness measures whole surface elements.

· Flatness is the condition of material/component in which all the elements of the specified surface lies on same plane.

· Flatness is the straightness of a plane at each and every point on the surface.

· Flatness tolerance need not relate to components datum line like straightness.

· Flatness controls the distance between high point and low point on the surface plane.

· Flatness tolerance zone is the distance between two parallel planes, one is on higher point of the surface and another is at lower point of the surface. To maintain flatness all the elements of the surface must lie between this two planes.

MEASUREMENT

· Flatness can be measured by using all the methods of measuring of straightness.

· During flatness measuring only thing is that we have to measure the maximum numbers of points on the whole surface.

· Flatness can be measures by using CMM or height gauge, need to move the stylus on the surface of the part.

· In CMM we can create the virtual reference plane and can measures the reading along this plane.

· The points should be measured along the length and width to ensure all surface is flatten under tolerance.

Comments

Post a Comment